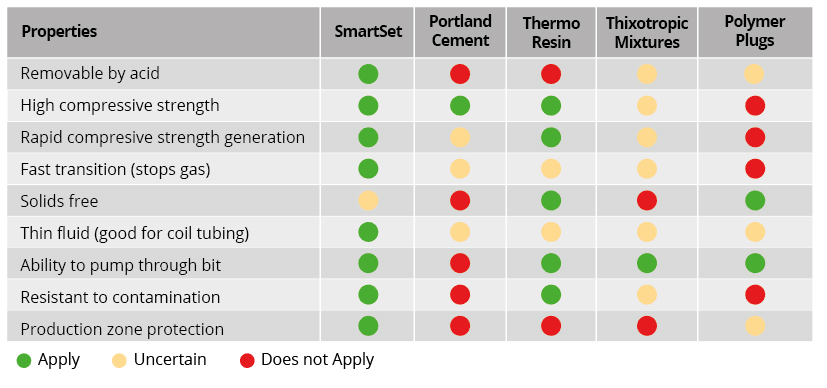

SmartSet® is designed to do what Portland cements and resins cannot do.

Solutions currently available for downhole temperatures up to 135°C (275°F).

Zero risk of “after placement” gas flows eliminates channeling. A major drawback of Portland cements is the transition between slurry and solid states, where cement gels (up to 30 minutes) and reduces hydrostatics, allowing gas to flow and form channels. SmartSet® always sets in under 120 seconds with zero gel strength generation.

Can be pumped over producing formation to temporarily isolate during remedial operations.

Production can be restored by acidizing or re-perforating after any up hole remedial work is finished.

Can be pumped through the bit and BHA in drilling applications due to its linear, and therefore predictable setting characteristics. Through bit plug placement of SmartSet® allows time-efficient curing of severe drilling fluid losses. A plug can be spotted and then drilling continue hours later without the need for a trip.

In a soft formation set across the build angle in a direction well. It will allow drill-out without kicking off.

Potential for use for arctic permafrost surface casing cement. The right-angle set can stop gas influx from shallow zones. Insulating properties limit heat transfer during drilling and production.

The set point observed in the field matches lab data typically within 3 minutes. Repeatability is the key to successful jobs. The set point is adjusted by our laboratory team by means of accelerators or inhibitors to meet job criteria for the planned pumping schedule and wellbore temperatures.